Little thought is given to the materials spaceships are made out of. In this post, we'll try to find out what are the likely materials being used, how the would affect the spaceship's design and extrapolate the effects of more advanced materials.

In science fiction, from the softest Star Wars rip-off to the hardest Andy Weir-inspired novel, little thought is given to construction materials, and when they do, they are either the habitual set of metals and plastics or their fictional counterparts.

Consider a long-term manned presence in space.

The astronauts or colonists will eventually number more and want to do more than when they started. They will grow. They will want more spaceships.

In science fiction, from the softest Star Wars rip-off to the hardest Andy Weir-inspired novel, little thought is given to construction materials, and when they do, they are either the habitual set of metals and plastics or their fictional counterparts.

Consider a long-term manned presence in space.

|

| A long-term Mars colony. |

Is it reasonable to sit, arms crossed, and pay for spaceship components to be delivered all the way from Earth's surface? Some purchases might be unavoidable, such as electronics or turbo-pumps, if you do not have the industrial base to build them on-site. Other components, such as simple propellant tanks and structural frames, can be made on-site.

This means that the we will use the materials available on-site, not those common on Earth. In Situ Resource Utilization (ISRU) is not necessarily limited to only producing rocket fuels after all.

What are these materials? Will they be different on the Moon than on Mars? What about the rest of the Solar System?

Desirable characteristics

If we had to reduce a spaceship's capabilities to the simplest description, it would be the ability to deliver a certain amount of DeltaV for a specific payload.

DeltaV depends on both the exhaust velocity of the propellant leaving the engines and the ratio between the fully-fuelled (wet) mass and the empty mass.

The payload depends on the mission. The exhaust velocity varies with technology levels, thrust requirements, propellant choice and a whole host of other factors. What we will discuss, therefore, is how the capabilities of a rocket are affected by its wet to dry mass ratio.

A larger mass ratio increases the DeltaV capacity and allows the spaceship to accomplish more missions more quickly.

The simplest way to increase the mass ratio is to decrease the mass of the structural frame, the engine mounts, the propellant tanks and all components that are not ejected out of the spacecraft's rear end.

There is a lower limit to how far you can reduce the dry mass. It is determined mostly by the forces the components must endure during flight. For example, a paper-thin propellant tank would buckle and rip under the forces of a lift-off on Earth.

From these facts, it is easy to understand why the materials being used in a spaceship are critical to its ability to perform its intended function.

The aerospace's industry obsession with composites, carbon fibres and aluminium honeycombs can be reduced into one concept: specific strength, or the strength to weight ratio.

A material with a high specific strength allows a lighter component to handle the same forces as a heavier material with lower specific strength. This means a lower dry mass, a better mass ratio and more DeltaV capacity for the same payload.

High specific strength is the first desirable characteristic.

Different elements are available in different concentrations depending on their location. They combine into compounds and chemicals that make them easier or harder to extract and refine.

Moon

The Moon is an interesting case.

Vacuum allows for unusual rocket designs. Low gravity (16% of Earth's) means that rockets can take off using much reduced thrust, which in turn greatly lowers structural requirements. The deltaV to reach orbit is about four times lower than on Earth.

Together, these factors mean that regular aerospace materials become exceptionally effective at reducing the spaceship's dry mass, while others become viable. For example, the dry mass of a lunar launcher can be 4% of that of a terrestrial launcher for the same payload, or alternatively, materials with 25 times lower specific strength become usable.

Lunar ISRU will focus on the upper layers of the lunar soil. It varies between 5 and 15 meters' depth, depending on the location of craters. It is unlikely that early manned presence would have the tools or energy to dig further than that.

The lunar soil has peculiar properties. It is something we have analyzed thoroughly. The Apollo missions brought back 382kg of samples to be tested in laboratories, so we have a good idea of what resources potential missions will have access to.

If we had to reduce a spaceship's capabilities to the simplest description, it would be the ability to deliver a certain amount of DeltaV for a specific payload.

DeltaV depends on both the exhaust velocity of the propellant leaving the engines and the ratio between the fully-fuelled (wet) mass and the empty mass.

The payload depends on the mission. The exhaust velocity varies with technology levels, thrust requirements, propellant choice and a whole host of other factors. What we will discuss, therefore, is how the capabilities of a rocket are affected by its wet to dry mass ratio.

A larger mass ratio increases the DeltaV capacity and allows the spaceship to accomplish more missions more quickly.

The simplest way to increase the mass ratio is to decrease the mass of the structural frame, the engine mounts, the propellant tanks and all components that are not ejected out of the spacecraft's rear end.

|

| To reduce structural mass, today's rockets are made just strong enough to survive a vertical launch. Even small sideways forces cause them to break up. |

From these facts, it is easy to understand why the materials being used in a spaceship are critical to its ability to perform its intended function.

The aerospace's industry obsession with composites, carbon fibres and aluminium honeycombs can be reduced into one concept: specific strength, or the strength to weight ratio.

|

| Even jet airliners benefit from the mass savings of high specific strength materials. |

High specific strength is the first desirable characteristic.

Different elements are available in different concentrations depending on their location. They combine into compounds and chemicals that make them easier or harder to extract and refine.

Moon

The Moon is an interesting case.

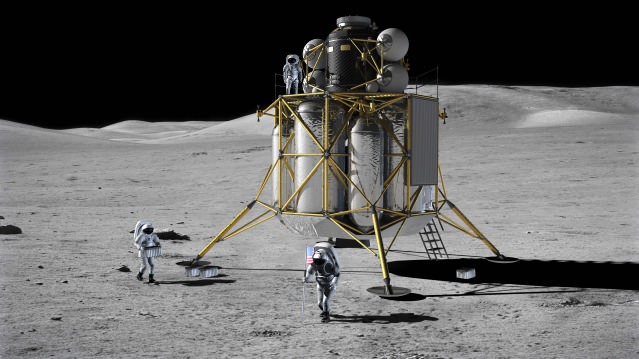

|

| Altair lunar lander |

Together, these factors mean that regular aerospace materials become exceptionally effective at reducing the spaceship's dry mass, while others become viable. For example, the dry mass of a lunar launcher can be 4% of that of a terrestrial launcher for the same payload, or alternatively, materials with 25 times lower specific strength become usable.

Lunar ISRU will focus on the upper layers of the lunar soil. It varies between 5 and 15 meters' depth, depending on the location of craters. It is unlikely that early manned presence would have the tools or energy to dig further than that.

The lunar soil has peculiar properties. It is something we have analyzed thoroughly. The Apollo missions brought back 382kg of samples to be tested in laboratories, so we have a good idea of what resources potential missions will have access to.

What we find is an abundance of oxygenated metalloids and common metals. Like terran soil, there is a lot of silicon, aluminium and iron. Like on Earth, very little of the lighter elements are locked up in rocks, such as carbon and nitrogen.

The lack of carbon means many strong steels become difficult to produce. The same is true for recently popular materials such as carbon fibres.

On the other hand, lunar soil contains much more titanium and magnesium than on Earth. Titanium has high specific strength, but is difficult to manufacture. Aluminium alloys such as Magnox in nuclear reactors, Alusil for temperature-resistant engine components and or even Sapphire can be used.

|

| Reasonably flexible. |

However, common aluminium alloys such as the 7075-T series are difficult to make, because certain additives such as selenium and zinc are very rare on the Moon.

Iron could be used, but its vulnerability to thermal expansion stresses and transition from ductile to brittle in low temperature environments make it and its alloys very much inferior to aluminium and titanium.

Lunar concretes and glasses are likely to form the bulk of common components. The are plentiful, easy to make and require less refining than metals.

The simplest concrete is just lunar rocks (aggregate) bound calcium-rich dirt (concrete) and water. A waterless version can substitute with sulfur, which reduces its ability to survive direct sunlight temperatures but allows it to be made just about anywhere on the Moon. Over time, it loses strength as the concrete loses water or sulfur into vacuum.

Aluminosilicate glass can be made with local materials as it does not require the boron additives found in more familiar borosilicate glass, or the sodium in soda-lime glass. Both are rare on the moon, at 0.000002% and 0.1% abundance respectively. Lunar glass melts at about 1300K, has compressive strength between 100 and 140 MPa and can be made very chemically inert. The presense of iron oxide contaminants turns it an opaque black. Without contaminants, it is the Gorilla Glass used on iPhones.

|

| Lunarcrete. |

Glass fibres are extremely strong. Tensile strengths in the 10GPa ranges have been measured on individual strands, allowing for a specific strength up a thousand times better than aluminium or steel allows. Glass-Fiber Reinforced Concrete with 4.5% fibre content gains 30-40% increases in compressive strength. GLARE is an aluminium panel/glass fibre composite with a specific strength up to six time higher than stainless steel. Basalt fibres offer similar performance without any metals, but requires a source of low-iron basaltic rock. These might be found in lunar lava tubes.

Mars

The deltaV requirements and the higher gravity on Mars means that spaceships must pay closer attention to the weight of their materials than on the Moon. They still enjoy a 3x deltaV and 2.5x thrust advantage compared to Earth.

Martian soil has also been the subject of a lot of research and experimentation, especially in the search of volatiles (water, ammonia) that support life.

|

| Mars soil after drilling by rover. |

|

| Of most interest is the last line: "soil-free rock" |

Steel is an excellent choice. Iron from the soil, carbon from the atmospheric CO2 and no free oxygen to corrode the result makes it ideal for this environment.

Plastics are another option. Combining carbon dioxide and water can create hydrocarbons, basically, plastics of various densities and strengths. Of greatest interest is UHMWPE, or ultra-high-molecular-weight polyethylene. This plastic has an extra-ordinary specific strength when spun into Dyneema or Spectra. However, this is an energy intensive process.

|

| UHMWPE has many uses. |

Carbon fibres can be used to make large, lightweight structures, but they might be difficult to manufacture. Modern examples include the massive 12m diameter cryogenic propellant tank designed by SpaceX or the Apple Campus 2 Theatre's 42m wide roof.

|

| Relative abundance of heavier elements on Earth, Moon, Mrs and Vesta. |

Non-planetary bodies

The majority of the resources outside of planets are found in the large moons orbiting Jupiter and Saturn.

We have yet to directly sample the surfaces of these moons, but we have pretty good estimates on what we can find...

.... which is mostly water ice and igneous rock. This means oxygen, silicon and usually iron.

|

| Saturn's moon Hyperion. |

|

| SpaceX's massive carbon fibre tank. |

The consistent, low temperatures also mean that materials such as iron do not suffer much from thermal expansion. Aramid fibres such Kevlar can be exposed directly to sunlight, as there is much less damaging ultraviolet than on Earth.

Other than the gas giants' moons, there are the numerous rocky asteroids and comets in our Solar System. These exist as an extreme variety of resources in all shapes, sizes and orbits.

Rocky asteroids form 85% all asteroids. They are very similar in composition to the most ancient pieces of rocks on Earth's crust: rich in water, very poor in metals and containing elements such as sulfur and calcium in significant amounts. Carbonaceous asteroids also contain a lot of carbon and nitrogen as methane and ammonia.

Rocky asteroids form 85% all asteroids. They are very similar in composition to the most ancient pieces of rocks on Earth's crust: rich in water, very poor in metals and containing elements such as sulfur and calcium in significant amounts. Carbonaceous asteroids also contain a lot of carbon and nitrogen as methane and ammonia.

Comets have solid cores but are mostly water ice and other frozen elements. Dusty comets have a fairer fraction of their mass as metal-poor dust, on their surface and interspersed in the ice. It would not be wise to rely on a metal-based construction industry here.

In many cases, these bodies suffer from extreme changes in sunlight. They often lack resources for building strong components (hydrocarbons, iron), and those that have them (metallic asteroids) are usually devoid of the volatiles necessary for life (water, ect).

The upside to all this is that most asteroids, comets and even moons have negligible gravity. The acceleration of spacecraft travelling to and from these bodies can be as low as a few milligees. Even if the deltaV requirements for quick travel can be high, it can be produced over long periods of time, such as with nuclear-electric engines.

This greatly reduces the structural requirements on spacecraft. Very simple materials, such as ice, can be squirted into large hollow shapes. Pure ice can have a tensile strength of up to 3MPa, a compressive strength of 25MPa, and can be made much stronger with the addition of practically any sort of fibre, even steel wire. Pykrete, the result, is bulletproof with only 14% fibre.

Summary

Spaceships and space habitats will be made of materials available locally - this is a further development of the concept of In-Situ Resource Utilization. For most of the Solar System, this means using unfamiliar materials.

The smaller the planetary body, the lower the deltaV needed and the slower the rocket needs to accelerate to take off. This lowers the specific strength requirements on the materials used. For the smallest asteroids, simple ice mixed small amounts of fibre are all that is needed.

Next, we will look at advanced materials, solar-system-wise availability and how construction materials can fit into worldbuilding.

In many cases, these bodies suffer from extreme changes in sunlight. They often lack resources for building strong components (hydrocarbons, iron), and those that have them (metallic asteroids) are usually devoid of the volatiles necessary for life (water, ect).

The upside to all this is that most asteroids, comets and even moons have negligible gravity. The acceleration of spacecraft travelling to and from these bodies can be as low as a few milligees. Even if the deltaV requirements for quick travel can be high, it can be produced over long periods of time, such as with nuclear-electric engines.

This greatly reduces the structural requirements on spacecraft. Very simple materials, such as ice, can be squirted into large hollow shapes. Pure ice can have a tensile strength of up to 3MPa, a compressive strength of 25MPa, and can be made much stronger with the addition of practically any sort of fibre, even steel wire. Pykrete, the result, is bulletproof with only 14% fibre.

Summary

Spaceships and space habitats will be made of materials available locally - this is a further development of the concept of In-Situ Resource Utilization. For most of the Solar System, this means using unfamiliar materials.

The smaller the planetary body, the lower the deltaV needed and the slower the rocket needs to accelerate to take off. This lowers the specific strength requirements on the materials used. For the smallest asteroids, simple ice mixed small amounts of fibre are all that is needed.

Next, we will look at advanced materials, solar-system-wise availability and how construction materials can fit into worldbuilding.

Mars could also make metallized Mylar film for various purposes...volatile storage tanks, inflatable antennas and solar collectors, solar sails and whatnot.

ReplyDelete...Could export carbon based products to Mercury to make UHMWPE there, actually. Lots of energy there.

Mylar is a good material. It would slightly difficult to find the elements needed to render the metallic layer inert, as there isn't a lot of fluorine lying around for Teflon, or chromium for stainless steel, but since it only needs to be a very thin layer, it might not be an insurmountable problem.

DeleteIf you are exporting products, something I will talk about in Part II, then Saturn's moon Titan is an excellent source of hydrocarbons.

Producing plastics on Mars is energy-intensive and requires the use of valuable water. Taking hydrocarbons directly from Titan might end up being cheaper if the propulsion infrastructure is in place.

Could be instrumental to getting to Titan in the first place.

ReplyDeleteAlso, good place to manufacture Kuck Mosquitoes. Make Mylar down on the Martian service, ship it up to Phobos, make Mosquitoes, and launch them into the asteroid belt or at a comet with a stationary tether.

Why not simply make the Mosquitoes on Phobos? It has all the resources Mars has, such as iron, oxygen, water and maybe even CO2 ices.

DeleteGood point.

DeleteJust thinking that Phobos might have CO2 ices, but CO2 on mars is just a high-pressure pump away-you don't even have to mine for the stuff-and you're going to be making Mylar and other lightweight plastics down there anyway for the colony's use, so why waste a plastics factory on Phobos?

Sorry, I was working on your 'launch them into the asteroid belt' comment and assumed that this plastic production was for interplanetary trade purposes. In that case, Phobos has a tiny gravity well and deltaV penalty compared to Mars.

Delete*surface, bah.

ReplyDeleteGiven the economic incentives to build things as inexpensively as possible, I suspect Zuppuro's Ice ship concept will be quite common and even popular, with the only real difference from his reference design being the "bag" will be made out of some form of fibreglass spun from regolith or basalt. If you want more strength, the bag can be a complex 3d structure that fills the internal space with fibres to reinforce the ice. A layer of paper deposited aluminum on the outer surface of the filled bag to provide some insulation and protect against leakage and you have instant spaceship hull.

ReplyDeleteMuch of the engineering for future space structures may also be based on tension structures as well, for lightness and strength

Quite right!

DeleteThe simplicity of this design also opens up avenues for a plausible home-grown rocket. Using nothing more complex than an ice cube tray microgravity, the ice ship can be built as a collage of ice bubbles. Cover the bubbles in asteroid cement for insulation and fill then with water, then install a solar concentrator on one end, a habitat on the other, and you've got an asteroid hopper!

The use of tension structures is the reason why I look at compressive or tensile strength in materials interchangeably.

Thanks for this wonderful post. Precision Drawell ia leading manufacturer of Stainless Steel Fibre in India.

ReplyDeletewow, nice post,

ReplyDelete