Let’s have a look at nuclear ‘thermal-electric’ engines and their advantages.

Limits

of Nuclear Thermal Rockets

Nuclear

thermal rockets (NTR) work by heating up a propellant. Heat flows from the

nuclear fuel to the propellant, raising its temperature. The higher the

temperature, the faster the propellant expands in a nozzle, allowing for higher

exhaust velocities.

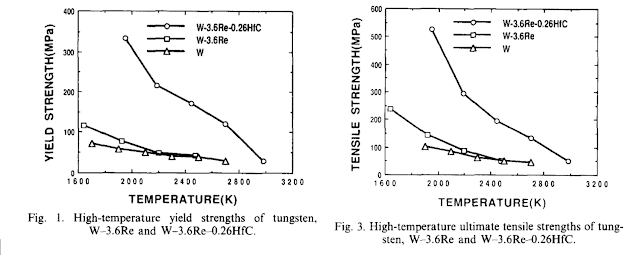

It is

evident that higher temperatures allow for higher exhaust velocities. Nuclear

rocket designs have always tried to push the temperatures up to the limit that

their materials can handle.

From

Project Rover, we have 2750K as the maximum temperature that was sustained.

This is not enough to break up the hydrogen propellant into individual H ions,

so the exhaust velocity they could have achieved in vacuum is 8.86km/s or an

Isp of 904s.

Project Timberwind went further with carbide fuel particles that could handle 3100K, and the Russian nuclear space program ramped up the temperatures to 3500K.

By operating at these higher temperatures, they gain a major step up in exhaust velocity by causing the hydrogen propellant to thermally decompose. The result is an exhaust with half the molar mass.

By operating at these higher temperatures, they gain a major step up in exhaust velocity by causing the hydrogen propellant to thermally decompose. The result is an exhaust with half the molar mass.

At

3500K, an exhaust velocity of 12km/s is possible, which is an Isp of 1233s.

This

of course is an excellent level of performance. An exhaust velocity four times

greater than that of chemical rockets but with propulsion systems with a

similar power density means that spacecraft can perform missions with four

times the deltaV requirements.

For

example, a hydrogen-propelled nuclear thermal spaceship with the same overall

mass as a chemical-fuel spaceship could go to the Moon and back four times or

reach Mars twice as fast.

But

what if we wanted to go even further?

This

is where the limits of nuclear thermal rockets impose themselves.

At

temperatures over 3200K, you must accept that the nuclear fuel will get eaten

away by hot hydrogen because the protective materials used to shield the

uranium fuel, such as Zirconium or Niobium ceramics, fail.

At

4000K, the use of carbon materials is unsustainable as carbon readily vaporizes

even without being attacked by superheated propellant. Perhaps temperatures as

high as 4500K are possible with the most heat-resistant material we’ve

discovered yet; Tantalum Hafnium Carbide.

But,

even at 4500K, the exhaust velocity achievable is 13.7km/s, only 14% better

than with the conventional materials.

A

known solution to this to accept that the reactor will melt, or even operate in

a gaseous state. This is the idea behind liquid core or gaseous core rockets.

A

liquid or vapor core nuclear rocket can produce core temperatures as high as 6000K.

These

are promising solutions, but we will not be focusing on them in this post. They

have problems of their own, such as spewing out radioactive fuel along with the

propellant, and have not yet been demonstrated to work.

Instead,

let’s look at the real world alternative.

The Nuclear

Electric Alternative

If

the temperatures required to achieve higher exhaust velocities are too great to

handle, then it is smart to side-step the challenge and use another form of

propulsion.

Electric

propulsion does not heat up the propellant but accelerates it in other ways.

Exhaust velocities of 60km/s are being produced by space probes right now, and 210km/s has been demonstrated.

Nuclear

reactors are the preferred method for providing a reliable source of power in

space that does not depend on distance from the Sun or finite stores of

chemical fuels. A few dozen kilograms of uranium can release megawatts for years.

This

power can be converted into electricity by moving heat from a high temperature

(reactor) to a low temperature (radiator) and forcing the temperature gradient

to do work with something like a turbine.

The

efficiency of the process depends on how work is extracted. A thermoelectric

device might have an efficiency of 10%, a turbine 40% and a magnetohydrodynamic

generator 60%. These efficiencies are lower than those on the ground because we

have to reduce the temperature gradient and maintain the cold end (the

radiators) at a relatively high temperature so that the cooling surfaces

required stay manageable.

Radiating

away the heat from a 100 Megawatt heat source at 400 Kelvin would need the

spaceship to extend radiator surfaces totalling 69,000m^2. Even lightweight

carbon fins would impose a mass of 345 tons, and this is without the pumps and

piping required to move the heat around. Increasing the radiator temperature to

800 Kelvin might halve the generator’s output but it would reduce the radiator

mass down to 43 tons. When dealing with spacecraft that are very sensitive to

mass increases (as each kg gained requires exponentially more kg of propellant

to be added), this is a worthwhile tradeoff.

The

electricity generated is then used to power an electric propulsion system.

‘Ion’

or ‘plasma’ engines are of this sort. They feature very high exhaust velocity

but very low power density. While a nuclear thermal rocket enjoys 100kW to 1MW

per kg, an electric engine would struggle to produce more than 2kW per kg. Most

modern examples achieve less than 1 kW per kg.

The

low power density of the electric propulsion system, the mass of the radiators

and mass of equipment like turbines all add up to create a nuclear-electric rocket (NER) where each kW of power is paid for by several kilograms of mass.

This,

coupled with the higher exhaust velocities cutting thrust (exhaust velocity and

thrust have an inverse relationship), means spacecraft that necessarily

accelerate very slowly. Uncrewed cargo craft won’t mind the wait. Human

transports and crewed ships would prefer to use much more propellant to speed

up their interplanetary trips.

The poor Bimodal rocket

There

have been attempts at trying to gain the benefits of both nuclear thermal and

nuclear electric propulsion.

A

previously proposed solution is the bimodal rocket (BNTR). In one mode, it is a

thermal rocket. In another mode, it is a reactor the provides heat to a

generator that powers an electric propulsion system.

The

problem with this approach is that switching between the two modes of

propulsion requires that equipment for both types be present at all times. This

means that you need the nozzle of a nuclear thermal rocket as well as the

radiators for an electrical generating system. The equipment for the mode not

in use becomes dead weight.

Furthermore,

nuclear cores cannot be made hot and powerful for the thermal mode as well as

stable and endurant for the electric mode. The 3000K+ temperatures and high

pressures that made a good nuclear thermal mode clash with the need to reduce

temperatures and protect the nuclear fuel so that it can provide heat for days

to months on end. All designs end up compromising on performance.

The

result is sub-optimal performance in either mode. A lower temperature thermal

mode with diminished Isp and thrust, and a reduced efficiency electric mode

with diminished power output.

The true hybrid

The

nuclear thermal-electric rocket (NTER) design is meant to combine the two

different types of propulsion into a true hybrid that does not waste the fact

that cryogenic propellants are wasting their cooling capacity (as Alan

Bond put it) in NTRs and NERs.

There

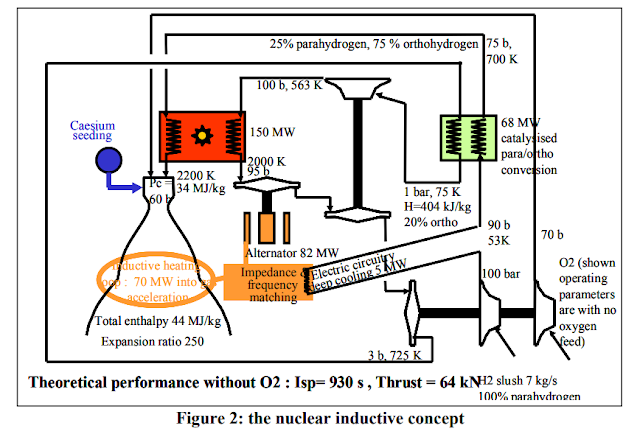

are many variants possible, but we will explain the design using one of the

most promising of them: the intercooled Brayton-cycle nuclear thermal-electric

rocket with magnetohydrodynamic booster. It will be using liquid hydrogen as

propellant.

Let’s follow the journey of the liquid hydrogen from the propellant tanks, through the nuclear electro-thermal rocket and out of the nozzle. The pressure, temperature and other numbers being mentioned are only indicative of what would be expected from this design.

Let’s follow the journey of the liquid hydrogen from the propellant tanks, through the nuclear electro-thermal rocket and out of the nozzle. The pressure, temperature and other numbers being mentioned are only indicative of what would be expected from this design.

The

short version is that the hydrogen makes two passes through the reactor core.

Once at high pressure, another time at low pressure. Many megajoules of energy

are extracted from each kilogram of hydrogen that makes these loops. The energy

is converted into electricity, which is used to further accelerate the thermal

exhaust going down the nozzle using an electric booster.

1-Cooling

1-Cooling

The

hydrogen starts out as a cryogenic fluid. A small impeller or autogenous

pressurization of the propellant tanks pushes it out at a low pressure.

The fluid passes through a heat exchanger. It absorbs heat from one of the steps below and becomes a cool gas (perhaps 150 Kelvin) with low pressure (1 bar).

The fluid passes through a heat exchanger. It absorbs heat from one of the steps below and becomes a cool gas (perhaps 150 Kelvin) with low pressure (1 bar).

About

2.2 MJ of heat is absorbed for every 1 kg of hydrogen that passes through.

2 –

Compression

The

cool hydrogen gas can now pass through a two-staged compressor.

The

first stage multiplies the pressure 50-fold. It releases the hydrogen at a

pressure of 50 bar. Compression heating raises the gas’s temperature to 468K. We

use temperature changes to track how much energy is consumed or released, as

pressure differences are recovered in later steps. The first stage of the compressor

requires 4.54 MJ of energy per kg of hydrogen.

The

warm hydrogen passes through an intercooler. This is where the heat absorbing

ability of cryogenic hydrogen is exploited. Liquid hydrogen from the propellant

tanks is used to bring the 50 bar hydrogen’s temperature down to 313K.

The

second stage compressor multiplies the pressure 3 times. It produces warm

hydrogen gas at 150 bars and a temperature of 430K. It would require 1.68MJ/kg

of hydrogen.

The

total energy consumed by the compressor stages is 6.22MJ/kg.

3 –

High pressure heating

The

warm hydrogen enters the high pressure section of the reactor core. By passing

over the fuel elements, it absorbs energy and reaches a temperature very close

to that of the uranium fuel itself. In this example, it will be 2500K.

4 –

Expansion

The

hot hydrogen enters a turbine. It expands, decreasing in pressure and

temperature. The turbine blades are propelled by the hydrogen’s expansion to

extract 29.18MJ/kg. The blades will need to be hollow so that they can be

actively cooled in order to survive the initial 2500K temperatures.

Hydrogen

exits the turbine at a temperature of 698K and a pressure of 1 bar.

5 –

Generator

The

turbine and compressors are connected by a single shaft. That shaft can be

connected to an electric generator. Energy consumed by the compressors and

extracted at the turbine allows for a net gain. In this example, it is

22.96MJ/kg.

6 –

Low pressure heating

The

turbine’s exhaust now passes through the low pressure segment of the reactor.

It is heated again to 2500K and Cesium is added. The Cesium would represent a

tiny portion of the hydrogen flow (0.1% or less by mass) but greatly increase

its electrical conductivity.

7 –

Nozzle with booster

The

nozzle is ringed with electromagnets. They act upon the conducting exhaust gases

like an electric plasma rocket to further accelerate the exhaust. Electricity

comes from the turbine-driven generator.

Without

any electric boost and a large vacuum-optimized nozzle, the rocket’s exhaust

velocity would be 8.45km/s, which is an Isp of 862s. However, adding the

22.96MJ/kg gained from the generator allows for an exhaust velocity of 10.8km/s,

or an Isp of 1104s!

Naturally,

this is an ideal scenario where everything is 100% efficient. It would more

realistic to add perhaps just 17MJ/kg to the hydrogen, increasing the Isp to

‘only’ 1046s.

This

is still a very significant improvement. We are obtaining greatly improved Isp

from a solid nuclear core, without the increase in temperatures that would

otherwise be needed from a purely thermal rocket. On the contrary, the 2500K

temperature allows for greatly improved core endurance and reduces thermal

stresses on all components involved.

Only

one mention of this type of propulsion exists outside of a handful of

scientific papers: the game “dV:

Rings of Saturn”. It features plenty of hard SF technologies, including an

example of this type of propulsion system. The engine is called the “Rosatom-Antonov K-37: Turbine Nuclear Thermal Rocket with Lorentz-effect accelerator” which uses

the steps described above to achieve an exhaust velocity of 15km/s, impossible

for a solid-core nuclear rocket otherwise.

Here you can watch an excellent start-up sequence made for that engine.

Nuclear Thermal-Electric Variants and Performance

We

will now go through a list of potential variants, each with their own

advantages and disadvantages, and work out a likely performance level. As the

technology progresses or assumptions change, the performance that is calculated

will also change. We will use a ‘near future’ set of performance assumptions

and then extrapolate to a ‘further future’ where materials have improved and

technology has progressed somewhat.

Simple

Thermal

It is

important to establish a reference point to see what the relative advantage the

NETR has over the NTR.

A

large-scale engine that can be built from proven designs would achieve a power

density of 1 MW/kg and operate at 2800K using current technology. This gives it

an Isp of 912s (8.9km/s) using liquid hydrogen and 635s (6.2km/s) with liquid

methane.

A

more advanced version would operate at a higher temperature and use stronger,

lighter materials. 3200K core temperature allows for a liquid hydrogen Isp of 1214s

(11.9km/s) and a liquid methane Isp of 679s (6.6km/s).

Note

that at this point, increasing the temperature up to the absolute limits of

currently understood materials technology (<4200K) would only increase Isp

by 15% over the advanced design, but the use of dense refractory ceramics would

cut into the power density.

Thermoelectric

In

this variant, the Seebeck effect is used to generate electricity. A

thermoelectric couple stands between a heat source and a cold sink so that the

temperature gradient drives electrons to produce a current.

We

have a >2800K heat source available and cryogenic propellants as the cold

sink. No single thermoelectric generator can handle such a huge temperature

gradient in one step. It is more likely that multiple generators are stacked on

top of each other, each only handling a smaller temperature gradient. The

maximum temperature that can be handled today by thermoelectric materials is about

1300K.

Propellant

would first need to be pumped to the stack of thermoelectric generators (TEGs) to

keep the cold end at a low temperature. If it is 500K, then 7MJ/kg of cooling

can be obtained from liquid hydrogen, and 1.43MJ/kg from liquid methane.

Heat

can be delivered to the top stack of thermoelectric generators by a heat pipe

directly connected to the nuclear reactor’s core. It extracts electricity from

the temperature difference between the hot end and the cold end. The ideal

Carnot efficiency across 500 to 1300K is 61.5%.

The

efficiency of a thermoelectric device is given by:

Efficiency

= (1-Tc/Th) * ((1+ZT)^0.5 -1) / ((1+ZT)^0.5 + Tc/Th)

Tc is

the cold end temperature in Kelvin.

Th is

the hot end temperature in Kelvin.

ZT is

a characteristic value depending on the thermoelectric materials.

Using

modern thermoelectric materials with

a ZT of 1.2 across to 500K to 1300K temperature range, an efficiency of 16% is

to be expected.

A

negligible amount of inefficiency comes from having to pump the propellant

through the piping from the propellant tanks, through the heat exchangers and

into the reactor core.

This

means that the 7MJ cooling capacity of liquid hydrogen is spent handling the

(1-0.16): 84% of reactor heat that is wasted. 1.33MJ becomes electrical energy.

Liquid methane’s 1.43MJ/kg cooling capacity becomes 0.27MJ of electricity.

An advanced

thermoelectric generator that could handle 2000K temperatures and have a ZT=2

could raise its efficiency to 27%. It would extract 2.59MJ of electricity from

the cooling capacity of hydrogen, and 0.53MJ from methane.

Advantages

of this design include having nearly no moving parts and only a single passage

of the propellant through the reactor. It would be tough and reliable. Tens of thousands of

hours of operation are expected.

Disadvantages

are the low efficiency and great weight of the thermoelectric generators.

Thermionic

The

high temperatures available from the reactor core can cause metals to directly

emit electrons. This is the thermionic effect that can be used to produce

electricity.

Two plates, an emitter and a receiver, are held close to each other. The emitter is heated to a high temperature, causing it to release electrons. Electrons jumping the gap between the two plates and are collected as an electrical current. However, the receiver absorbs all of the thermal radiation from the receiver, which is the main source of inefficiency. We want the temperature gap to be as high as possible, so a receiver with a low emittance and low temperature is ideal. The emitter can be made of materials like molybdenum or tungsten; in fact, it is even more temperature resistant than the nuclear core and can therefore be as hot as we want. The cold end is a problem though.

Two plates, an emitter and a receiver, are held close to each other. The emitter is heated to a high temperature, causing it to release electrons. Electrons jumping the gap between the two plates and are collected as an electrical current. However, the receiver absorbs all of the thermal radiation from the receiver, which is the main source of inefficiency. We want the temperature gap to be as high as possible, so a receiver with a low emittance and low temperature is ideal. The emitter can be made of materials like molybdenum or tungsten; in fact, it is even more temperature resistant than the nuclear core and can therefore be as hot as we want. The cold end is a problem though.

In

previous examples of nuclear thermionic power, having a low temperature

receiver conflicted with the need to have a high radiator temperature to get

rid of the waste heat into vacuum. We have access to cryogenic propellant which

can absorb heat even at very low temperatures, so this is not as much of a

problem.

We

know that high efficiencies are already possible. A Japanese solar propulsion research

effort produced a thermionic converter (TIC) that held an

emitter at 1850K and cooled the collector to 1100K. They managed 57% of the

maximal Carnot efficiency, resulting in 23.2% actual efficiency.

A

modern nuclear thermo-electric rocket using a thermionic converter could raise

an emitter’s temperature to 2700K, only slightly less than the core temperature

by using heat pipes, which do not require any electricity to move heat (only a

temperature difference).

An

electric pump or exhaust bypass drives a low pressure pump to push propellant

through a heat exchanger that cools the thermionic collector. It could hold it

at 1000K.

The

maximum Carnot efficiency across this temperature gradient is 64.3%. Near term

performance might be 30% of this maximum, achieving 19.3%.

Hydrogen

can absorb 14.2MJ/kg when heated from liquid to 1000K. With the thermionic

converter’s efficiency, we can produce 3.4MJ of electricity from each kilogram

of hydrogen.

Methane

absorbs 3.4MJ/kg in the same situation, which allows 0.81MJ of electricity to

be produced.

The

hot gases from the collector are then sent into the reactor to be heated

themselves up to the 2800K core temperature, and then pushed through a nozzle.

The electricity produced by the thermionic is then used to accelerate the exhaust from the

nozzle.

An

advanced version of this is might manage to achieve 60% of the ideal Carnot efficiency

between 3200K and 1000K, for an actual efficiency will of 41.2%.

Hydrogen

now allows 9.9MJ of electricity to produced and methane allows for 2.4MJ.

The

advantages of this design are that it can handle very high temperatures and

extract more power using the cryogenic propellants. It is just as resistant to

damage as the thermoelectric option.

Disadvantages

are low power density, although much better than a thermoelectric converter.

One

thermionic variant attempts to use three thermionic steps, all with the same

emitter temperature but at higher and higher collector temperatures. Propellant

gas moves from step to step, making the most of its cooling capacity in a sort of cascade.

For

example, the first step could have the emitter at 2800K and the receiver at

500K. The second has the receiver at 1000K and the final step has the receiver

at 1500K.

Continuing

with the assumptions of the previous variant, thermionic efficiency between

2800K and 500K can be as high as 24.6%. Heating hydrogen from liquid to 500K

absorbs 7MJ/kg, so 2.3MJ of electricity can be produced at this step.

The

second step recycles the warm gases released from the first step and further

heats them to 1000K. Another 7.35MJ/kg of cooling capacity is available, of

which 1.76MJ can be extracted as electricity if we expect a thermionic

efficiency of 19.3%.

In a

third step, we further heat the hydrogen to 1500K. Thermionic efficiency falls

to 13.9%, which is still enough to gain another 1.25MJ from the hydrogen.

A

total of 5.3MJ of electricity of produced.

Re-doing

the numbers for methane, we generate 0.47+0.45+0.41: 1.33MJ.

An

advanced version might achieve 60% of the Carnot ideal, operate at a higher

3200K emitter temperature and add a 4th stage that raises the collector

temperature to 2000K.

The

efficiencies of the stages are 50.6%, 41.2%, 31.8% and 22.5% with collector

temperatures at 500, 1000, 1500 and 2000K.

The

electrical power generated at each stage using 1kg of hydrogen would be 7.2MJ,

5.2MJ, 3.6MJ and 2.4MJ for a total of 18.4MJ.

The

same figures for methane would be 2.5MJ, 1.3MJ, 1.2MJ and 0.87MJ, totalling

5.87MJ.

Clearly

the advantage here is that the cooling capacity of the propellant is used much

more efficiently. However, multiple thermionic converters would mean a

reduction in overall power density.

Thermoelectric

generators are limited in the maximum temperature they can handle. This limit

can be broken by another variant, a hybrid having the collector of a thermionic

converter act as the hot end of a thermoelectric generator.

Cryogenic

propellant can first cool the cold end of a thermoelectric generator to 500K. The

resulting warm gas is then used to cool the collector of a thermionic receiver

to 1300K. This hotter gas passes over the hot end of the thermoelectric

generator before entering the reactor core. The thermionic emitter meanwhile is

directly heated by the nuclear reactor to 2800K.

Thermionic efficiency can be as high as 16% between 1300K and 2800K. Thermoelectric efficiency would also be 16% between 500K and 1300K.

Starting

with hydrogen, we work out that the thermoelectric generator produces 1.33MJ of

electricity, and the thermionic converter produces another 2.29MJ for a total

of 3.6MJ.

Methane

following the same path allows for the production of 0.27MJ and 0.63MJ, totalling

0.9MJ of electricity.

An

advanced version of this with an improved thermoelectric generator of ZT=2

operating between 500K and 2000K, and a higher temperature thermionic converter

working between 2000K and 3200K, would have efficiencies of 27% and 17%

respectively.

It

would extract 2.59MJ and 4.83MJ of electricity from each stage for each kg of hydrogen,

a total of 7.4MJ. Each kg of methane yields 1.95MJ of electricity.

Also, thermionics can work with other power conversion systems to achieve a very high overall efficiency.

Also, thermionics can work with other power conversion systems to achieve a very high overall efficiency.

Thermophotovoltaic

Whereas

the blackbody radiation from a high temperature thermionic emitter is a source

of inefficiency, it can be used to produce electricity using thermophotovoltaic

panels (TPV). A thermophotovoltaic cell works like a photovoltaic cells, found

in solar panels, except that it can convert the wavelengths released by surface

less bright than the Sun into electricity.

Current

work focuses on increasing the efficiency of thermophotovoltaic systems using

emitters at lower temperatures (1000 to 2000K), with efficiencies of 25 to 38%

predicted. However, we can have a 2800K emitter directly heated by a nuclear

reactor, emitting wavelengths with a peak at 1000 nanometers. The conversion

efficiency can be as high as 56%

using multi-junction Gallium-Indium-Arsenic-Phosphorus photovoltaic cells. As

has been mentioned in a previous ToughSF post,

efficiencies as high as 61% have been demonstrated.

The

thermal radiation reaching these photovoltaic cells heats them up. Hot

photovoltaics quickly lose efficiency. It is therefore important to maintain a

temperature of about 300K, which we will accomplish using cryogenic propellant

as a heatsink.

Using

an efficiency of 50%, we find that a very high temperature thermophotovoltaic

system can produce 4.2MJ of electricity when using liquid hydrogen as the

heatsink.

An advanced

version of this set-up is very unlikely to increase the efficiencies or

temperatures much further. Power density could become better though.

The

advantage of thermophotovoltaics is their good power density relative to

thermoelectric or thermionic devices and an excellent overall efficiency.

However,

having to operate at low temperatures means that only a portion of the

cryogenic propellant’s cooling capacity is utilized.

Stirling

We now move to a very different method of

generating electricity. It works using two pistons that exchange gases as one

heats up and the other cools down. The motion of the pistons drive a generator.

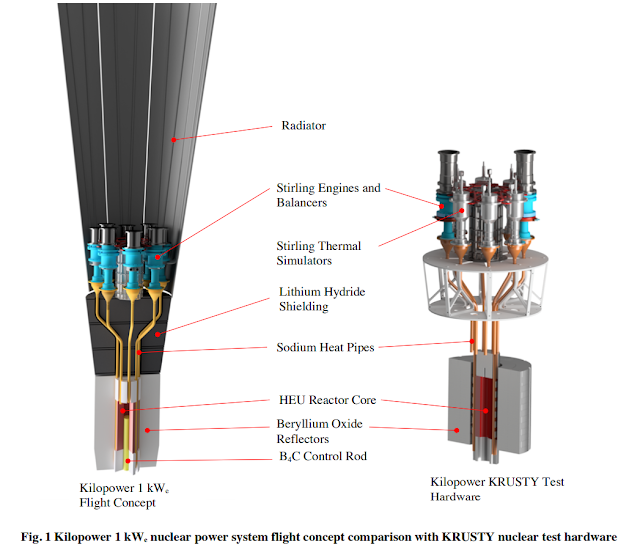

The Stirling cycle is currently the largest working type of nuclear power generation for space, with NASA’s ‘Kilopower’. We can cite from a test report on the design: “The engine thermal efficiency ranged from 30-34% at approximately 50% of Carnot”.

This is an interesting piece of information. It tells us that if have Stirling generator (STG) with the appropriate materials (perhaps tungsten carbide with an inert helium gas as the working fluid), we could have the hot end be directly heated by a nuclear core to 2800K, and the cold end by cooled by cryogenic propellant.

The Stirling cycle is currently the largest working type of nuclear power generation for space, with NASA’s ‘Kilopower’. We can cite from a test report on the design: “The engine thermal efficiency ranged from 30-34% at approximately 50% of Carnot”.

This is an interesting piece of information. It tells us that if have Stirling generator (STG) with the appropriate materials (perhaps tungsten carbide with an inert helium gas as the working fluid), we could have the hot end be directly heated by a nuclear core to 2800K, and the cold end by cooled by cryogenic propellant.

A 1000K cold end

means that the Stirling generators works across a 2800K to 1000K temperature

gradient, allowing for a maximum Carnot efficiency of 64%. If the generator

manages half of this maximum efficiency, we get 32%.

The cooling

capacity of liquid hydrogen heated up to 1000K is 14.2MJ/kg. 32% efficiency

means that 6.7MJ of electricity can be produced for every kg of hydrogen used.

Using liquid

methane allows for 1.6MJ of electricity to be produced.

A more advanced

Stirling design would use a free piston inside a linear generator to achieve 63% of the Carnot

maximum. When paired with a 3200K hot

end from a higher temperature nuclear core and the same 1000K cold end as

previously, we can expect an overall efficiency of 43%.

The electricity that can be generated when using hydrogen increases to 10.7MJ, and with methane to 2.6MJ.

The electricity that can be generated when using hydrogen increases to 10.7MJ, and with methane to 2.6MJ.

The main advantage

of Stirling

generators is that they can achieve a

better percentage of the maximum Carnot efficiency and have generally better

power densities than the alternatives. The gas in the cylinders can be

different from the coolants used to increase or reduce their temperature, so

they could theoretically handle very high temperatures without worry of chemical

degradation.

The disadvantage

though is that they work across a large temperature gradient, so they have to

be made robust and therefore heavier, and they have several moving parts that

reduce their operating lifetime. On spacecraft, they might need to include a

vibration absorber.

Brayton

Intercooled

This is the design we described earlier when

explaining the nuclear thermal-electric concept. Propellant is used to drive a

Brayton cycle. Energy is extracted from the temperature difference between the

heat exchanger and the turbine exit and is used to drive a shaft which spins an

electrical generator.

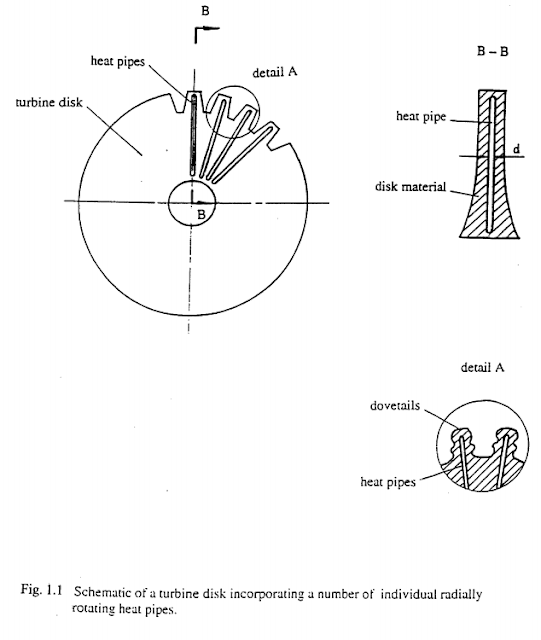

The process depends on a number of factors, such as

the pressure ratio and the heat capacity of the gases involved. Therefore, it

is not possible to use a simple percentage figure for the efficiency.

Using the ‘modern’ nuclear core as out heat source,

we would expect temperatures as high as 2800K to be used to maximize

efficiency. However, turbine blades must bear the brunt of these temperatures. They

have to spin at high speeds and maintain sufficient strength to not break off

or slowly elongate. What’s worse is that with a turbine on a spaceship, it is

not really possible to cool the turbine blades using cold air from the exterior

or cold water from an endless reservoir. The result is hard limits on the

temperatures that turbogenerators can work with.

The highest a typical uncooled nickel-based turbine blade can handle is 1200K.

The highest a typical uncooled nickel-based turbine blade can handle is 1200K.

More recent alloys based on niobium have managed

several hundreds of hours under 1700K conditions, but the best we have are silicon

nitride or silicon

carbide ceramics that have been

tested for thousands

of hours up to 2000K.

Let’s run some numbers using hydrogen.

We’ll start with two compressor stages, each

increasing the gas pressure 10-fold. Temperature increases by a factor 1.95

after each stage. An intercooler between the stages absorbs some heat.

If we set the entry temperature at 410K, the

hydrogen will exit the first stage compressor at 800K. It enters the

intercooler, where cold liquid hydrogen is used to absorb the heat added by the

compression. The compressed gas is cooled down to 410K while the liquid

hydrogen is heated into a 400K gas, ready to be sent into the compressor. 5.7MJ

of heat energy is exchanged per kilogram. Going through the second stage

compressor allows it to reach 100x the initial pressure and a temperature of

800K.

We heat the hydrogen in the reactor core to 2000K.

High pressure, high temperature hydrogen now enters

the turbine stage to be expanded so that its energy can be extracted as

mechanical work. Expanding across a 100-fold pressure difference lowers the

temperature by a factor 3.8, so it exits at 526K.

The compressors

have consumed 11.4MJ to compress each kilogram of hydrogen. The turbine can

extract 23.2MJ, so the net result is 11.8MJ for each kg of hydrogen. It is then

converted into electricity by an alternator.

If we

apply real world efficiencies to these steps (95%, 90% and 95%), we are more

likely to gain 8.4MJ instead. This is an overall efficiency of about 52%.

The

turbine exhaust goes through the reactor core again to be re-heated an exit

through a nozzle, where the electrical energy gained is used to increase

exhaust velocity.

Methane

in this same Brayton cycle consumes 1.1MJ/kg in the compressors, extracts 6.4MJ/kg

in the turbine and gains a net of 5.3 MJ of electricity for each kilogram used.

With a realistic overall efficiency of 56%, this is 4.4MJ.

A

more advanced turbine can use hollow turbine blades made of ceramic materials actively

cooled by a liquid metal heat pipe. Hafnium carbide can form the outer layer

while silicon carbide forms the core. This arrangement minimizes the use of the

very dense hafnium-rhenium-tungsten

alloy while exploiting the fact that the interior of the turbine blade can be

kept at the <2000K temperatures where the lighter silicon carbide retains

its strength.

Active

cooling is how we manage to increase turbine performance with

existing materials, only that we are applying the concept here to much improved

materials.

Thanks

to these improved materials, we can operate at 2800K.

We

will also use bigger compressors to reach even higher pressures, perhaps 500

times the initial pressure. This is similar to the performance of simple

turbopumps on rocket engines today, like the Raptor,

where pressure at the exit is 643 bar.

To

maximize the intercooling effect, we can separate the compression into three

stages. In between each stage is an intercooler that makes use of the cryogenic

propellant’s cooling capacity.

Let’s

run the numbers on a sample design.

Three

compressors aiming to multiply pressure 500-fold could be arranged to achieve

10x, 10x and 5x. This would increase the temperature of hydrogen gas 1.95x,

1.95x and 1.59x respectively.

If

hydrogen gas enters the turbine inlet at a temperature of 200K, it exits the

first compressor stage at 390K. The compressor consumes 2.66MJ for every

kilogram that passes through.

The

first intercooler reduces the hydrogen’s temperature back down to the

compressor’s entry temperature. In a heat exchanger, hydrogen gas cools down

from 390K down to 200K and cold propellant heats up from 22K to 166; this is an

exchange of 2.66MJ of heat for every kilogram.

The

second compressor stage also consumes 2.66MJ/kg and releases 390K gas. It

passes on the gases to a second intercooler that reduces their temperature to 358K.

From the cold side of this intercooler’s heat exchanger, we get the gases at

200K that will go to feed the turbine inlet. From the hot side, we get the

gases at 358K that will enter the final compression stage.

In

the third compressor, 3.1MJ are consumed and compression heating causes the

hydrogen gas temperature to increase from 358K to 571K. The hot pressurized

hydrogen is then fed into the nuclear reactor core.

Hydrogen

exiting the core sits at 2800K. A turbine expands it down a 500-fold pressure

gradient. The expansion cools the hydrogen back down to 460K and 38.2MJ of

energy can be extracted from each kg of hydrogen having passed through the

turbine. It is converted into electricity by an alternator.

The

net energy produced as electricity in this design is 29.78MJ. With realistic

efficiencies, this is 27.4MJ.

We

work out that the overall efficiency is 76%.

Methane

used in this design allows for a realistic energy gain of 8.4MJ/kg. Methane’s overall efficiency

is 73%.

A lot

more energy is being extracted by these turbines for each kilogram of cryogenic

propellant than with the previous generators. Turbines are also very lightweight

for the power they handle, and they can be paired with electrical generators

that are already achieving over 15kW/kg in power density. Superconducting

versions of the latter could achieve 40kW/kg. Put together, we can see a power

conversion system that exceeds the performance of previous examples ten-fold in

terms of watts per kilogram of equipment mass.

This

advantageous level of performance is why turbomachinery is the preferred method

of generating power on Earth and in space.

One

of the disadvantages of turbines using ceramic blades however is that they are

brittle at lower temperatures and prone to cracking if heated up too quickly.

They generally have a shorter lifetime than generators with few to no moving

parts, shorter still if they start getting knocked around by impacts during

combat or buffeting during re-entry.

This

makes turbomachinery relatively fragile.

It is

also possible to add a regenerator when the exhaust from the turbine is cooler

than the gases going through compressors.

For

example, if the entry temperature to the compressor was 400K and the exit

temperature was 781K, while the turbine exhaust temperature is 526K, like in the

modern 2000K design above, then we use the turbine exhaust as the cold side of a

heat exchanger and the compressor gas as the hot side.

The

regenerator allows these gases to reach an intermediate temperature. In this

case, the average of 781K and 526K is 653K. The cooling effect on the compressor

gas is therefore 128K. 1.8MJ of heat energy regenerated in this manner can

reduce the need to use up the cryogenic propellant’s coolant capacity by the

same amount. That cooling capacity can be better used elsewhere.

In

the advanced Brayton generator example described previously, two intercoolers

are used between three compression stages. The first intercooler uses up most

of the cryogenic propellant’s cooling capacity, so the second stage can only

reduce the hydrogen gas’s temperature by 32K before it enters the third stage.

Using

a regenerator would have allowed a much more significant temperature reduction

and a corresponding decrease in the compression consumption of the third

compressor stage, as it would be working with cooler gases.

This

translates into significant portion of that saving ending up as more

electricity at the end. The question however, is whether the increased weight

from the regenerator allows for a gain in overall efficiency that does not significantly

affect overall power density.

The

other variants possible using a Brayton cycle are a Double Loop design, where

the exhaust of one turbine is fed into a second turbine, or a Closed Loop,

where cryogenic hydrogen is only used to cool down turbine exhaust so that it

can be recycled, much like a radiator would do.

Magnetohydrodynamic

This

is yet another completely different method of generating electricity. A

magnetohydrodynamic generator (MHD) uses magnetic fields to slow down a

conductor moving through it. The kinetic energy of the conductor is directly

converted into electricity.

Hydrogen,

methane or other good rocket propellants are not well suited for use directly

in an MHD generator, as they need to be ionized to become good conductors (as

plasmas), but this only occurs at very high temperatures. As they cool down

while going through the MHD generator’s ducts, they become neutral gases again.

Several solutions have been proposed: seeding the propellant with elements that easily

ionize at lower temperatures, ionizing the propellant with an electron beam or

having a closed loop MHD generator where a separate fluid is kept.

A closed loop is

what we’ll focus on for now instead of the open cycle. It circulates an easily ionized element like

cesium, potassium, rubidium or xenon between a heater, MHD duct, cooler and

pump. The heater transfers thermal energy from the nuclear reactor core.

Extreme temperatures are possible. The hot fluid travels down the MHD ducts,

where some of its energy is extracted. In doing so, the fluid loses pressure

and temperature. It then passes through a cooler, where we will bring in

cryogenic propellant to act as a heatsink. The cooler fluid is then pumped back

up to the design pressure to go through the loop again.

Technically,

this is another Brayton cycle. Compared to a turbine, the MHD variant gains the

ability to handle any temperature but loses the ability to extract most of the

fluid’s energy. There are designs for MHD generators that work with 4000K

temperatures and higher, something impossible to send through a turbine.

Let’s

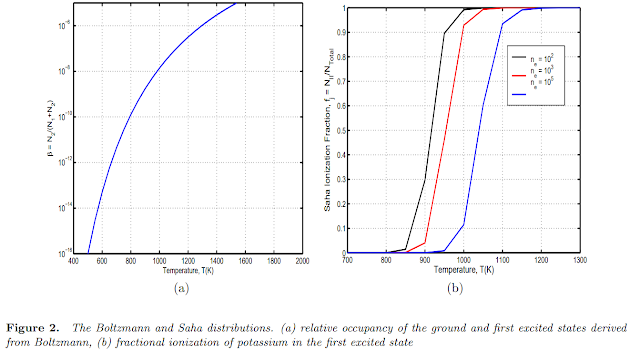

consider a MHD generator realizable today.

Helium

is used, seeded with potassium. The hot end temperature is 2800K, like the

reactor core providing the heat. The cold end temperature is limited by the

point at which potassium stops being ionized and returns to being a neutral

atom. This happens at about 1000K.

This

means that the maximum Carnot efficiency is 64%. Inefficiencies in the MHD

generator and the pumping requirements means only about half of that is

available, so overall efficiency is 32% with the help of intercoolers and

regenerators.

If we

set the cooler temperature to 500K, then 7MJ/kg of cooling capacity can be

obtained from liquid hydrogen, and 1.43MJ/kg from liquid methane.

This

translates into an electrical energy gain of 3.29MJ for each kilogram of liquid

hydrogen consumed, or 0.67MJ for each kilogram of liquid methane.

A lot

more can be done with a more advanced MHD generator and a higher temperature

nuclear reactor.

For

one, the helium/potassium mix can be heated to 3200K. This increases the

maximum Carnot efficiency to 68.8%, assuming the same exit temperature of

1000K.

We

can also use superconducting magnets for the MHD generator and the electric

motors turning the compressors. It might allow us to use an overall efficiency

figure of 66%.

Putting

all these advanced features together, and assuming a similar cooler temperature

of 500K, we can manage to gain 13.5MJ from liquid hydrogen or 2.78MJ for liquid methane.

Of

course, the MHD generator cycle can be greatly improved. 1000K gases at the

exit of the MHD duct are hot enough to drive another power generating cycle. It

can be another Brayton cycle using a turbine, where we can extract another 40%

of the remaining energy between 1000K and 500K, which would improve overall

efficiency of the advanced MHD design to 79.6% (and the energy gain by a

whopping factor of 1.66x, to 22.41MJ with liquid hydrogen and 4.6MJ with liquid

methane). Or, a humble TEG device that can only obtain a few percent of the

remaining energy but does not add any moving parts.

There

are several advantages to an MHD generator. It has a very high power density,

no moving parts except for the pumps and the nuclear reactor would only need to

have one single-pressure section that the propellant goes through once. It can

easily be used as a topping cycle to power generating systems that cannot

handle extreme temperatures but are able to use the MHD’s exhaust. In fact, it

is best to have Magnetohydrodynamic, Brayton and Thermionic/Thermoelectric all

working in series.

Each cycle operates best at a certain temperature range. Magnetohydrodynamic generators thrive at extreme temperatures, turbines prefer lower temperatures that their turbine blades can handle, while thermoelectric generators can operate at low temperatures. Overall efficiencies using a 'combined' cycle approaches 80%. The highest power density combination is likely to be a turbo-MHD design.

Each cycle operates best at a certain temperature range. Magnetohydrodynamic generators thrive at extreme temperatures, turbines prefer lower temperatures that their turbine blades can handle, while thermoelectric generators can operate at low temperatures. Overall efficiencies using a 'combined' cycle approaches 80%. The highest power density combination is likely to be a turbo-MHD design.

However,

having a high temperature fluid mixed with reactive metals going round and

round a loop will lead to corrosion issues that reduce the lifetime of the

generator. The magnets, which need to stay cold to maximize efficiency, have to

be placed right next to superheated gases. Superconducting magnets have even

bigger issues with thermal management.

Electric

boosters

In

this section, we’ll have a look at how the electrical energy produced by the

generators in the previous section can be employed to increase exhaust velocity.

ResistoJet

A resistojet is a

simple heating device that has propellant run over tungsten or other refractory

material so that temperature is increased through conduction.

Tungsten

can handle temperatures as high as 3500K. This is usually higher than the

temperatures of the nuclear cores themselves, as they are under other design

constraints (such as surviving the intense radiation).

If we

employ a resistojet as the electrical booster to a ‘modern’ nuclear thermal

rocket, we can raise the temperature of the exhaust from 2800K to 3500K. This

might seem like a minor increase, but there is a significant benefit that comes

with hydrogen propellant thermally decomposing into individual atoms (H2 to H).

This halves the average molar mass of the exhaust, meaning that Isp increases

from 912s (8.94km/s) to 1270s (12.4km/s).

For

an advanced nuclear core already operating at 3200K, the benefit is so minor as

to be negligible since it has already thermally decomposed the hydrogen and

would only receive an Isp increase from 1213s (11.9km/s) to 1270s (12.4km/s).

Efficiency

is said to be about 80%.

Arcjet

An arcjet

heats up propellant to very high temperatures using electric arcs. It is not

limited by the melting point of any material, but it does suffer from constant

erosion of its electrodes.

Temperatures

as high as 12,000K are achievable, and since the exhaust gases have already

been heated up by a nuclear reactor, we can dismiss ionization losses and only look at the 80-90% thermal efficiency.

In

this electric booster, we are not temperature limited but energy limited.

Any

propellant entering the electrical booster should be considered a plasma (or

soon will be!). This means that it has a heat capacity ratio of 1.66 and a

fixed heat capacity of 20.37J/mol/K.

In

practical terms, it takes 20.37kJ to heat up 1kg of monoatomic hydrogen by 1

Kelvin, and 6.36kJ to heat up 1kg of methane thermally decomposed into its constituents

(average molar mass 3.2g/mol) by 1 Kelvin.

If we

have 6MJ available for each kg of hydrogen propellant, we can increase the

temperature by 265K (assuming 90% efficiency) from 3200K to 3465K, with a

corresponding increase in exhaust velocity of just 4%.

Those

same 6MJ delivered to an arcjet running on methane would increase temperature

by 849K from 3200K to 4049K, increasing exhaust velocity 12.4%...

Microwave,

Laser and RF Induction heating

Microwaves

or lasers can be used to directly heat propellant, with the choice being made

depending on how well their wavelengths are absorbed.

RF

Induction uses an alternating magnetic field to act on a conductive propellant.

Efficiency

with these methods can be good (>60% efficiency lasers) to great (>90%

efficient induction coils) and they have no temperature limits. Erosion is not

a problem, so they can operate for a very long time. Power density is also

improving every year.

Unlike resistojets or arcjets, there are no practical temperature limits, only the heat flux that the walls can handle.

Unlike resistojets or arcjets, there are no practical temperature limits, only the heat flux that the walls can handle.

Electromagnetic

acceleration

This

category of electric booster uses electromagnetic forces to directly accelerate

the propellant using Lorentz, Hall or Ponderomotive effects. More electrical

energy directly becomes kinetic energy, making them much more effective than

simply heating the propellant.

We

are interested in electrodeless plasma thrusters. Because the source of our

plasma is a nuclear reactor core emitting very high temperature gases, to which

an easily ionized seeding material can be added, we will not have to suffer the

losses from using equipment required to generate plasma. That already

significantly improves our potential efficiency.

Some

of the simpler designs, like a Pulsed Inductive Thruster, are unusable as the

propellant from the reactor is continuous.

Others

like the ponderomotive plasma engine, based on the non-heating part of the VASIMR engine, the

travelling wave plasma accelerator or

an ELF

design can directly convert electricity into kinetic motion with

efficiencies exceeding 80% using a variety of propellants and have practically

unlimited exhaust velocity (the VASIMR in high gear is supposed to reach an Isp

of 30,000s!).

The use

of superconducting magnets can bring the power density of the electrical

booster to acceptable levels, so they do not affect propulsion mass

requirements too much. Even better, they do not significantly increase the temperature of the exhaust, so they can operate for much longer with lighter materials.

A highly efficient power generating cycle using all the tricks in the book (recirculating, combined cycles, regeneration and so on) using these types of accelerator could push Isp up to 1800s.

A highly efficient power generating cycle using all the tricks in the book (recirculating, combined cycles, regeneration and so on) using these types of accelerator could push Isp up to 1800s.

Use

of radiators

Using

cryogenic propellant as a heatsink does not mean that radiators must be

excluded from designs that can use them.

Power

generating cycles with higher temperature cold ends can radiate a lot of their

waste heat away using relatively small radiators. Each 1m^2 of double-sided

fins exposed to space can remove 7kW of waste heat when radiating at 500K, and

113.4kW at 1000K. Other radiator types can

handle this waste heat with very little equipment mass, by spraying liquid

droplets or electrostatically cycling dust in and out of a heat exchanger.

Therefore,

we can have power generating cycles that use radiators in addition to the

cooling capacity of propellant to extract even more electricity from each

kilogram consumed. Every MJ removed using radiators is a MJ that doesn’t using

up the propellant’s cooling capacity.

For

example, in the modern thermionic converter design, the collector plate is to

be held at 1000K. Each kg of liquid hydrogen used to cool it can absorb 14.2MJ,

so 1 kg/s of that propellant flow can be replaced by 125m^2 of double-sided

fins removing 113.4 kW/m^2.

A

spaceship can use radiators to increase the total amount of electrical power it

produces or reduce the rate at which propellant is consumed. Radiators can be extended

or retracted to change the power output or rate of propellant consumption,

which is a nice option to have when facing different situations such as combat

(where radiators could be damaged) or prolonged accelerations (where a

maximally efficient electric engine is preferred).

Power

generating systems that can operate at different temperatures give even more

options. Small radiators can be used to handle high temperature heat (like a

thermionic converter operating between 2000 and 1500K) while lower temperature

steps that would require heavy thermal management could instead use a flow of

cryogenic propellant. When radiators need to be retracted, propellant handles

all cooling requirements. If the extra power is not needed, the power

generating cycle only works with the high temperature steps and cuts off the

lower temperature ones.

Impact

of the technology

Two

types of spacecraft benefit the most from Nuclear Thermal-Electric propulsion

technology.

The

first are rapid transports that wish to minimize interplanetary travel times.

The second are warships.

Rapid

transports aim to travel along very energetic trajectories using a lot of

deltaV. They want the rapid acceleration of nuclear thermal propulsion but also

the Isp of nuclear electric propulsion.

Rapid

acceleration is needed to escape low orbits near planets quickly, both

maximizing the Oberth effect and reducing the amount of time spent traversing

radiation belts. High thrust chemical engines are why Apollo missions could get

to the Moon in 3 days at

the cost of 4km/s of deltaV, but a proposed electrical

propulsion system would take 9 months to slowly spiral its way there.

A

nuclear thermal rocket can deliver this high thrust as well as double the

specific impulse. With the thermal-electric design boosting Isp from around 1000s

to nearly 2000s, the deltaV capacity is doubled again without losing much

acceleration.

This

NASA document

describes how a spaceship with both high thrust and high Isp propulsion options

ends up having better performance than either option alone. NTER can realize

that ideal.

Warships

benefit even more from nuclear thermal-electric propulsion.

It

would have three competing requirements. The first is to generate electrical power

so that it can use lasers, electromagnetic accelerators, active sensors and

other energy-intensive equipment. The second is to protect itself from enemy

fire. The third is to keep up with its targets and run away from missiles.

The

first two requirements are in conflict with each other because generating

electricity also produces waste heat, and getting rid of waste heat generally

means exposing large radiator panels to space. These panels cannot be armored

(it would defeat their function) and so become large weakspots that when

damaged, prevent electricity from being generated.

The

second and third requirements clash because deltaV needs must be met by large

propellant reserves. The best propellants, like liquid hydrogen, are very

voluminous and covering propellant tanks with armor becomes a massive penalty.

An opponent can bring more weapons to the fight if they do not have the same

mass penalty, while you would be completely at the mercy of missiles and

kinetics if you cannot maneuver out of the way if you did not protect your

propellant tanks.

All

of these competing requirements can be met by a NTER.

By

using propellant as a heatsink, electricity can be generated while radiators are retracted or not even part of the design. This means a fully armored

spaceship with no weakspots can still generate the megawatts it needs to win a

fight. Furthermore, the electrical output can be used to increase the exhaust

velocity of denser, less optimal propellants like liquid methane. It is 6.7

times denser than liquid hydrogen, so the volume of propellant tanks for a

given mass ratio is correspondingly smaller. Less armor is needed.

A

warship using NTERs can eventually outrun spaceships using NTRs and outmatch

spaceships using NERs in both protection and acceleration.

From a science fiction perspective, it can allow for an argument to be made as to why there are no visible radiators. NTER propulsion means that we can consider 'softer sci-fi' designs as valid from a scientific standpoint.

You do not have to compromise between realism considerations and your choice of spaceship 'look'.

From a science fiction perspective, it can allow for an argument to be made as to why there are no visible radiators. NTER propulsion means that we can consider 'softer sci-fi' designs as valid from a scientific standpoint.

You do not have to compromise between realism considerations and your choice of spaceship 'look'.

Performed some edits with the help of 'Zerraspace'.

ReplyDeleteCan I swap the nuclear engine with fusion one?

ReplyDeleteFusion is a form of nuclear energy, you mean instead of fission. Personally i feel like the types of fusion that we are attempting conventionally from a high input energy would be to bulky but a means worth analyzing. a modern fission system works well and dependable, getting job done anywhere we need it. Hopefully we find a way to deal with the waste which is potencially useful.

Delete@felix

DeleteFusion is difficult because the 'exhaust' from a fusion reaction cannot be recycled into the reaction chamber after passing through the power generating cycle. You can use a fusion reaction as a heat source for a closed loop power generating cycle instead, but then you also run into the problem that mass flow rate for fusion reactions are very very small. You would find yourself strictly limited in the MWs you can extract in total.

@Bob

Fusion technology is progressing, and the only question is whether it will take a decade or a century to make it practical.

@MatterBeam

DeleteTrue, I hope it is closer to a decade. I am realising that both fission and fusion have a place in the future due to their individual benefits and trade offs. Was also wondering assuming metastable metallic hydrogen can be produced well using nuclear energy could that work in this concept in place of fission. SSTOs with Airbreathing rockets for example that could augment with electricity after reaching orbit. I enjoy your right ups and love the armchair engineer mindset they put me in!

@bob:

DeleteThanks! These posts are made to get you thinking.

I should warn you though, metallic hydrogen is on a completely different level. We've had fission rocket engines for decades, and regularly achieve fusion in lab experiments, but we've only ever made a doubtful speck of metallic hydrogen and never released it from pressure to see whether it is actually metastable...

This comment has been removed by the author.

DeleteTrue I was thinking it would make similar performance to a nuclear fission rocket without radiation shielding or the political backlash for launching from the surface.

DeleteCheck John Bucknell's approach to a reusable SSTO airbreathing vertical system: https://www.youtube.com/watch?v=wa3eIQHmf2I

Also check out this paper on theoretical metallic hydrogen rockets: https://web.stanford.edu/~cantwell/AA283_Course_Material/Silvera_metallic_hydrogen_paper.pdf

If you had some methane diluted metallic hydrogen (disappointed methane wasn't included in the paper) in a non-nuclear combined cycle turbo rocket, that would be an optimum indirectly nuclear launch craft. Assuming this form of hydrogen is more of energy storage, not a source, it would be produced by stationary reactors

While I recognize the benefits of running such a power generation system with no radiators (for combat or other such situations), it strikes me as odd that engines meant for less dangerous operation would forgo them. As you have shown in your Advanced Solar Energy in Space Part II, micro-wire radiators are capable of expelling nearly 200 MW/kg at 1200K. If used to expel waste heat at the 1000K "cool" side of the advanced MHD generator cycle, they would still handle nearly 90 MW/kg.

ReplyDeleteIt seems to me that using liquid hydrogen as an expendable coolant for power generation is much less useful than simply doing it the old fashioned way. Say 1kg of LH2 can provide ~14 MJ/kg at 1000K, and your rocket burns through 5 kg/s. Instead of wasting the potential exhaust velocity achievable, save the hydrogen and replace its cooling potential with 800 grams of radiator. This allows the low-pressure reactor output to be entirely separated from the high pressure reactor core (which should really use a mixture of helium/xenon or some such gas for better performance with less corrosion) and better overall efficiency, while still leaving the liquid hydrogen available for cooling cryogenic systems. The reactor still provides a very mass efficient way of ionizing the hydrogen propellant and getting it up to speed initially, but if you break propellant cooling potential away from electrical power generation, a much bigger boost can be provided through electrical acceleration. It would almost certainly reduce thrust to weight ratio the larger the electrical boost is in relation to reactor thermal power, but for a transport hauler or civilian vessel it should be much more fuel efficient.

The NTER exploits the cooling capacity of the propellant, and it can be used alongside radiators.

DeleteImagine this: a power generating cycle where heat is removed by radiators... but the coolant loops running from the generator to the radiator first passes through a heat exchanger where propellant is used to remove some of the waste heat.

And, you can have the power generating cycle be a closed loop only open on the hot end to the reactor and on the cold end to your combined radiator + heat exchanger. On the hot end, another closed coolant loop delivers heat from the nuclear core. This would mean that there only needs to be one single nuclear reactor core, at one pressure, that the propellant goes through only once... but you still obtain all the other advantages you just mentioned.

What do you think? It is always a waste to just send cold propellant directly into the reactor!

I agree with your statements here, I just wanted to point out that the cooling offered by even just a single kg of some advanced radiators can provide over 5x the cooling available from 1 kg of expended propellant. Yes, one shouldn't waste the cooling potential of the propellant, but I think it would be better put to use keeping the cryogenic engine components cool. Using it to provide additional cooling for the power generation cycle is a nice little bump, but the real purpose of additional heating of the propellant would be dissociation in my mind.

DeleteOn a related note, is there any form of electric propulsion that could handle the amount of energy generated by such a reactor setup? Most MHD or electrostatic designs I can find consume between 1 and 2 kW per kg of thruster, while this nuclear reactor cycle can probably top 50 kW per kg (again using numbers from your solar generators post). Using propellant as an expendable coolant for a isp boost is nice, but if your engine is limited to the pitiful thrust to weight ratio of traditional MHD thrusters, it would create a very interesting dynamic for combat ships; high isp (5000s +) using radiators for additional power production gives accelerations in the 50-100 mG range, while switching over to propellant cooled mode drops isp to ~1800-2000s at up to 1G acceleration.

Interesting, very interesting. A engine design that can use minimal to no radiator mass is a very enticing design indeed. Though I would like to know, is it possible to get torch levels of performance out this design?

ReplyDeleteWhen you mean 20 kilo tons yield worth of energy, do mean energy that is thrust or can tyres to electricity? I believe you meant the former.

ReplyDeleteOh I'm sorry, I though you asked that question in the Expanse post!

DeleteThe NTER gets harder and harder to scale up to higher exhaust velocities, which are necessary to meet the definition of a 'torch drive'. The is because the ratio of the heat energy that can be absorbed by the propellant becomes smaller and smaller relative to the power of the engine. The boost obtain becomes correspondingly smaller and smaller.

This is a really interesting concept. An engine that does not require radiators and can potentially use its fuel tanks as a heat sink for all other functions is fascinating! This engine, combined with a curved nozzle and several stealth functions in other posts, could lead to a very reliable stealth ship!

ReplyDeleteSorry to bother, but I was wondering something based on your explainations of what type of ships would benfit from this type of rocket. Can the NTR or NTER qualify as a torch drive?

ReplyDelete- Thank you

Any spaceship that uses cryogenic propellant and has a low exhaust velocity will benefit from this energy-recovery design.

DeleteAn NTER is like a turbocharger. It helps small engines get more power, but it will see limited benefit when you try to attach it to a massive nitro V8. So, it doesn't help a lot when using the design with a torch drive.

An NTER alone is like a turbocharger alone, it is not a torch drive.

NTRs and NTERs can get high thrust like a torch drive, but they have about 10% of the Isp needed to make for a torch drive.

Could this be combined with the nuclear thermal pulsed propulsion concept? If I'm not mistaken, that concept uses the neutrons to heat the propellant directly, which means that only 10 percent of the energy produced in the drive is of the right "quality" to attain high Isp. The concept originally called for radiators to remove the rest of the 90 percent. Could that energy be instead used to power and electric drive?

ReplyDeleteAlso, a study for a spacecraft that uses an NTER to achieve (hypothetical) remarkable performance:

Deletehttp://www.projectrho.com/public_html/rocket/realdesigns4.php#scorpion

I think you can definitely tap the 95% waste heat from the pulsed reactor to generate electricity - you have to move it to a radiator anyway so you may as well tap that temperature gradient. I do not think that putting that energy back into the exhaust using any of the methods described here will be meaningful, though. The pulsed NTR claims to boost ISP somewhere between 5,000 and 15,000 seconds. My guess is the electric thruster isn't going to meaningfully contribute additional energy to that exhaust.

Delete@Mr. Tucker

DeleteYes, that heat can be used to generate electricity, but it would need radiators because the flow of propellant would be insufficient to cool and NTER cycle.

@TheAnarchitect:

Electric thrusters have heated plasma to the point where Isp is boosted to 100,000s and beyond. They are very much capable of further accelerating the exhaust of a pulsed NTR. In fact, with a 50% efficient electric cycle, you could increase the amount of heat going into the propellant from 0.05 to 0.525 of the reactor output. That means a 0.525/0.05: 10.5x increase in propellant temperature and a 10.5^0.5: 3.2x increase in exhaust velocity!

The question really is whether the extra Isp makes up for the mass of the additional equipment necessary.

Woah, that's pretty good. At this point, aren't we looking at exhaust temperatures near fusion drive levels? At what point is the melting point of our rocket nozzle the limit? I used to think of the pulsed NTR as a modification of the regular NTR, but it seems like we'd need all the same support systems a fusion drive would, like massive radiators and magnetic nozzles. The advantage being, we know how to build a pulsed fission reactor, while we're still a little fuzzy on fusion.

Delete@TheAnarchitect Well, I was thinking that you could re-energise the flow in between "pulses". The engine "puffs", with acceleration circuits turned off, then as it cools, the waste heat is used to give whatever flow of fuel you see fit to run through it more energy (the concept never says the engine is turned off between pulses; rather it is running in stationary, AKA classic NTR, mode. Perhaps the velocity will not be quite as high as the puff, and the thrust will be lower, but at least you use the energy optimally.

Delete@Matterbeam True, but if if you use a combined cycle to remove a large portion of the heat, the radiators become far less cumbersome. I tend to think you're gonna want radiators either way on any nuclear fission system to run some form of electrical power generation. With regards to warships specifically though, remember that the pulsed fission concept can also switch to allow massively boosted thrust capabilities :) . And in that case, you can also keep the acceleration circuits turned on, to further augment the isp, while also maintaining your (now pretty ridiculous) thrust.

@TheAnarchitect: It will be a small quantity of plasma held away from any physical structure to prevent heat damage. The biggest difficulty with fusion is the ignition, not handling the exhaust or the heat. A better example would be the VASIMR plasma engine.

Delete@Mr. Tucker: I worry that the high Isp means a low mass flow rate, which in turn means that only a small amount of heat can be absorbed by the propellant before it enters the engine.

The pulsed fission concept is interesting and I haven't full explored it yet, and the possibilities of a hybrid pulsed/electrothermal fission reactor that you point to are quite promising.

I realize this thread is 7 years old, but I would like to note: Using the waste heat from a pulsed NTR for power is probably a bad idea, since it generates a HUGE amount of waste heat, and so really the main constraint is gonna be the radiators. The propellant can never take that much heat, unless you use such a high mass flow rate that Isp becomes poor. So, you're stuck with radiators. But furthermore, generating power means you reduce the temperature of the heat, and the Stefan-Boltzmann law scales with T^4. Meaning, if you halve the output temperature in order to generate electricity, the radiator area (and thus mass) balloons by 16x!!! So I think you'd probably want to stick with getting that heat out as high-temperature as possible.

DeleteI know of the pulsed nuclear thermal rocket concept that uses direct neutron heating of propellant to overcome temperature limits of heat exchanger materials, but it is essentially wasting 95% of its output: https://en.wikipedia.org/wiki/Pulsed_nuclear_thermal_rocket

DeleteCorrect on the penalty of generating electrical power.

Whenever I read about fusion-powered SSTOs, I keep thinking: "don't fusion reactions need a vacuum?" but this post gives me an idea; pre-heating cold propellant with the *outside* of a tokomak, spheromak, stellerator or other vacuum-chambered reactor vessel (letting the fusion neutrons heat the structure), then sending the hot gas into electric thrusters powered by the fusion reactor.

ReplyDeleteWould it be possible to have a Battletech-style, fusion-powered dropship capable of operating in the atmosphere with this method, then switch to a lower thrust, higher ISP mode of operation once in space?

I'm still at a loss as to how any NTR or NTER is going to operate with Methane. How is the decomposition and sooting problem resolved? I've seen numbers suggesting it starts creeping in at 600K and happens pretty much instantly at 1900K (https://www1.eere.energy.gov/hydrogenandfuelcells/pdfs/30535o.pdf).

ReplyDeleteThe NTER may be able to avoid this at the back end by heating the Carbon past its sublimation temp of 3900K with the electric booster, but how will the reactor fuel and other components operating at 2000K-3200K, or cooler components downstream before the high temperature boost, get by?

It's not as bad as it might first sound. Decomposition at 600K means that CH4 becomes a mix of CH3 and H, neither of which cause coking. As you increase the temperature, you will see CH2, CH and then C alone. That final product is what causes coking, and I believe it appears only at 2000K+

DeleteThe temperature it appears at will be increased by a high pressure environment. Coking is also slow to happen over hot surfaces too.

Finally, we have real world experience with very high temperature methane. The SpaceX Raptor engine uses methane propellant and there are sections where volatile carbon is released at 3500K+ temperatures, and yet the design is meant to be reusable with minor maintenance.

Wouldn't a Raptor pre-burner or terrestrial gas turbine get the benefit of a free H20 (perhaps supercritical) steam cleaning during operation, by virtue of combustion products?

DeleteNozzle throats don't seem like a problem, once the engine is sufficiently large, but a number of high performance NTR designs (twisted ribbon, MITEE) seem to have millimeter-scale propellant channels through the reactor fuel elements, where you do want things to get to or beyond 2000K.

The reason I'm concerned is because this paper (http://electricrocket.org/IEPC/7014.pdf) suggests that's how thick carbon build-up can get in a Methane arcjet on a timescale measured on the order of minutes or even seconds.

That is true. Having hot oxygen in the mix helps prevent soot from building up. A safer alternative for a nuclear thermal engine is to introduce an excess of hydrogen. The free hydrogen balances the chemical reactions away from single carbon and towards more CH/CH2/CH3.

DeleteI don't deny it is a problem, especially when heat exchange channels are very small. However, methane was considered for Project Rover and Robert Zubrin thinks it possible for a Mars mission using ISRU. Consider also that it might have some advantages; a carbon heat exchanger might prefer methane propellant instead of a corrosive hydrogen propellant...

And finally, if we designed for methane use from the start, we would have engineered solutions to prevent or delay coking. A hydrogen 'flush' might be required after a prolonged use of the engine, or some components are simply given a lifetime, like the air filter of a car.

I really don't see the reason people always go for methane over alternative propellants. Ammonia, for example, is denser (meaning less armor mass), doesn't have coking issues, and is much easier to ISRU, and it only has a little lower Isp than methane. Is there something about ammonia which makes it undesirable as a NTR/NTER propellant?

DeleteAmmonia is harder to source in the solar system, and in a really high temperature thermal rocket it breaks down into a plasma of 4.6 g/mol average mass compared to 3.2 g/mol for methane. That reduces the maximum theoretical Isp by 20%!

DeleteSo does the engine have to go through a first cycle and then the propellant recycle to gain benefits (kind of like when a cars turbo has to use initial exhaust gas to spool up the turbo, if so is there a way to inject something or add a smaller turbine to spool up the larger quicker?) Or does the system "charge up" to get the turbines and everything working at a certin level before being able to be used as propulsion (kinda like the old carburetor cars had to warm up before they were ready to go)

ReplyDeleteIf this approach to fusion https://www.hb11.energy/our-technology is the real deal then that could make a good torch drive. Uses only two lasers produces its energy in mostly charged particles, and the fuel hydrogen-boride is cheap makes an easily stored powder that can be easily compressed into pellets.

ReplyDeleteHydrogen-Boron fusion still releases about 0.2% of its energy as neutrons, and an even higher portion is lost as X-rays due to the higher temperatures involved. Also, it is has a lower exhaust velocity than Deuterium or He3 fusion.

DeleteStill, it is interesting as the 'cleanest' reaction.

Have you thought about a solar thermal-electric rocket using the same principles?

ReplyDeleteYes, I have! It will produce similar increases in specific impulse.

DeleteAt https://forum.nasaspaceflight.com/index.php?topic=50188.20 ,

ReplyDeleteI found another description of such engines